| Sometimes challenges just come your way. Hitachi asked us to install one of our Lincoln autolube systems on a ZW370 wheel loader; a fine machine, for anyone in the market for a 34-tonne, 5+ M^3 machine. Events, I should stress out of our control, meant the installation commenced by Roger in Tyne and Wear, was finished by Robin in Somerset! Another 'show kept on the road'. But your are only as good as your last 'performance'... |

|

0 Comments

Close to completion, Mansfield Sand are implementing a Trimble Loadrite C-Series conveyor scale and reporting package across 5 critical conveyors at their Two Oaks Quarry near Mansfield.

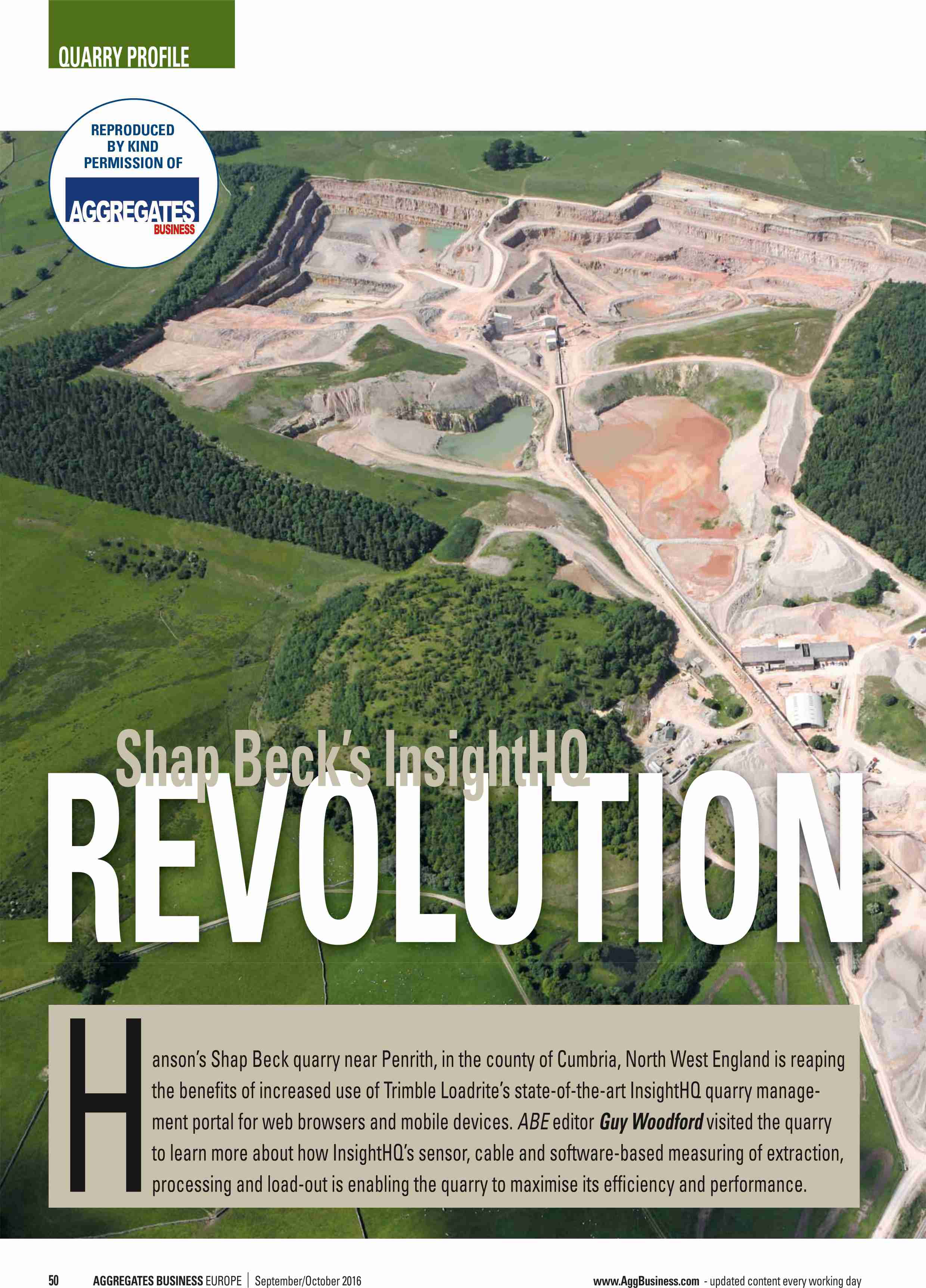

Demanding improved productivity data, the Trimble equipment was selected to provide accurate weighing and detailed reporting of productivity. Near real-time data can be easily accessed by any internet connected device through Trimble 'Snapshot' daily cumulative productivity information, whilst more detailed, periodic reports are emailed automatically, evidencing plant availability and utilisation and, total production for each product. Stock balances can now be ascertained more readily as well as overall productivity. Further enhancements will see moisture content factored and waste product automatically calculated with the deployment of virtual scales; summing totals from relevant inputs and outputs. Hanson's Shap Beck Quarry; reaping the benefits of Trimble's quarry productivity measurement and reporting system.

|

|||||||||

RSS Feed

RSS Feed