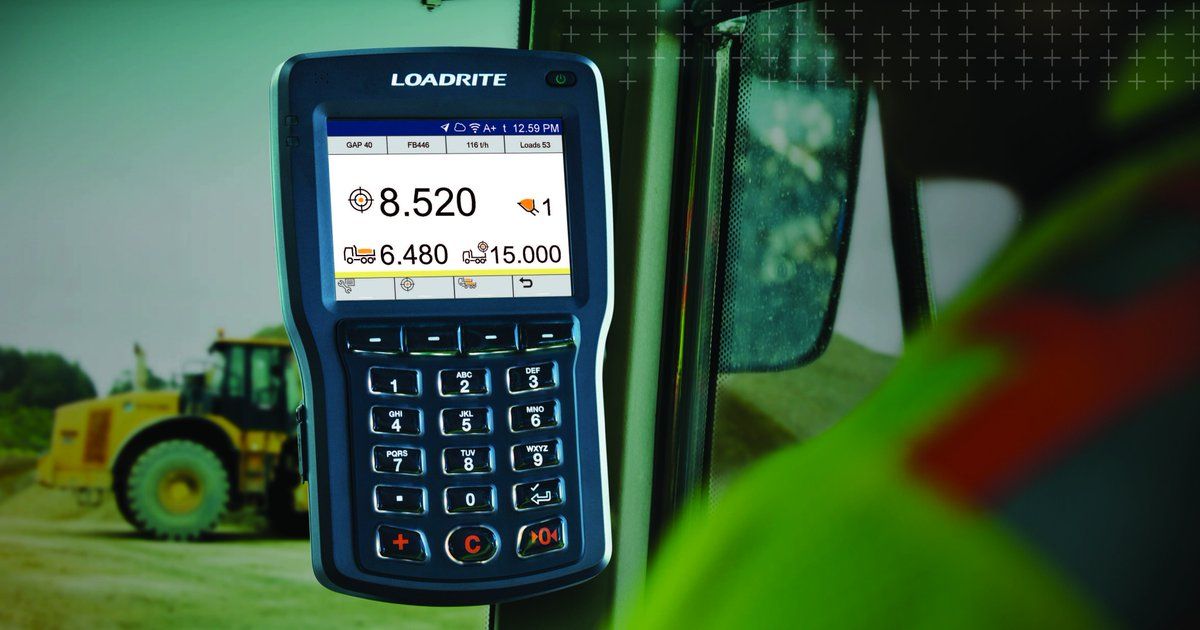

The Gloucestershire-based company, dedicated to helping business managers to improve the productivity of their mobile plant and equipment, has enjoyed an excellent working relationship with Loadrite for some time, as UK resellers of their Loadrite system. With their understanding of heavy industry, mobile equipment and harsh environments, Halomec was the natural choice for Smart Haul, the automated load and haul tracking system which can improve load and haul, reduce cycle times and boost tons per hour.

The Smart Haul system is almost completely automated and requires very little interaction from excavator operators. It can be fitted to any make or model of excavator, haul truck or ADT. The information it provides will help you detect delays, under-usage and bottlenecks. By combining payload data from the excavator scale with haul fleet monitoring and cloud reporting, it will also help to identify opportunities for additional productivity.

With specialist industry knowledge and an in-depth understanding of customers' needs, Halomec strives to provide and implement effective solutions for your business. Halomec’s team of regional engineers take time to understand your particular operation, getting to know your staff and how they operate, to deliver what you need for your business. They are trained to configure, install and service systems, precisely and safely.

As Tim Bannister, Product Manager at Loadrite, says: "Tracking progress in real-time, including material movement from dig to dump, enables hour-to-hour and day-to-day gains."

If your aggregate, quarrying, mining or construction business could be helped by moving material with greater speed and efficiency, get in touch with Halomec for a demonstration of the Smart Haul system to see what it can do for you on 01453 766444 or at info@halomec.com. See more at https://www.halomec.com.

RSS Feed

RSS Feed