|

Loadout Management System: LOADRITE 360 for Loadout

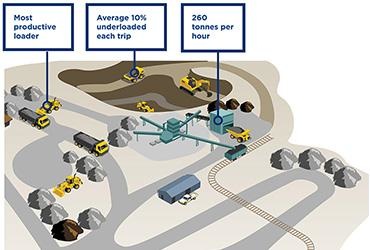

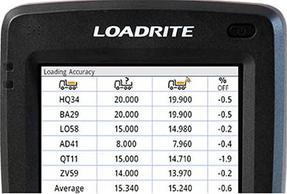

LOADRITE 360 is a connected quarry solution that can improve loadout operation through performance metric tracking, job data automation, and real-time 360º job visibility. LR360 connects the loader and weighbridge to provide data sharing of loadout jobs which result in greater efficiency, improved visibility and higher product sales. Reporting of haul truck production and process monitoring, driving increased production and limiting costs. |

|

How it works

LR360 decreases rework and miscommunication by wirelessly synchronizing data between the loader and the weighbridge.

|

What the Operators Say

|

| |||||||||||||||||||||